Hints and Tips

Contents

- Blocks

- Classification Yards

- Practical Yard Design Example

- Curve radius rule-of-thumb

- Curves

- Easyspline masoninte roadbed

- Glossary of Layout Design Terms

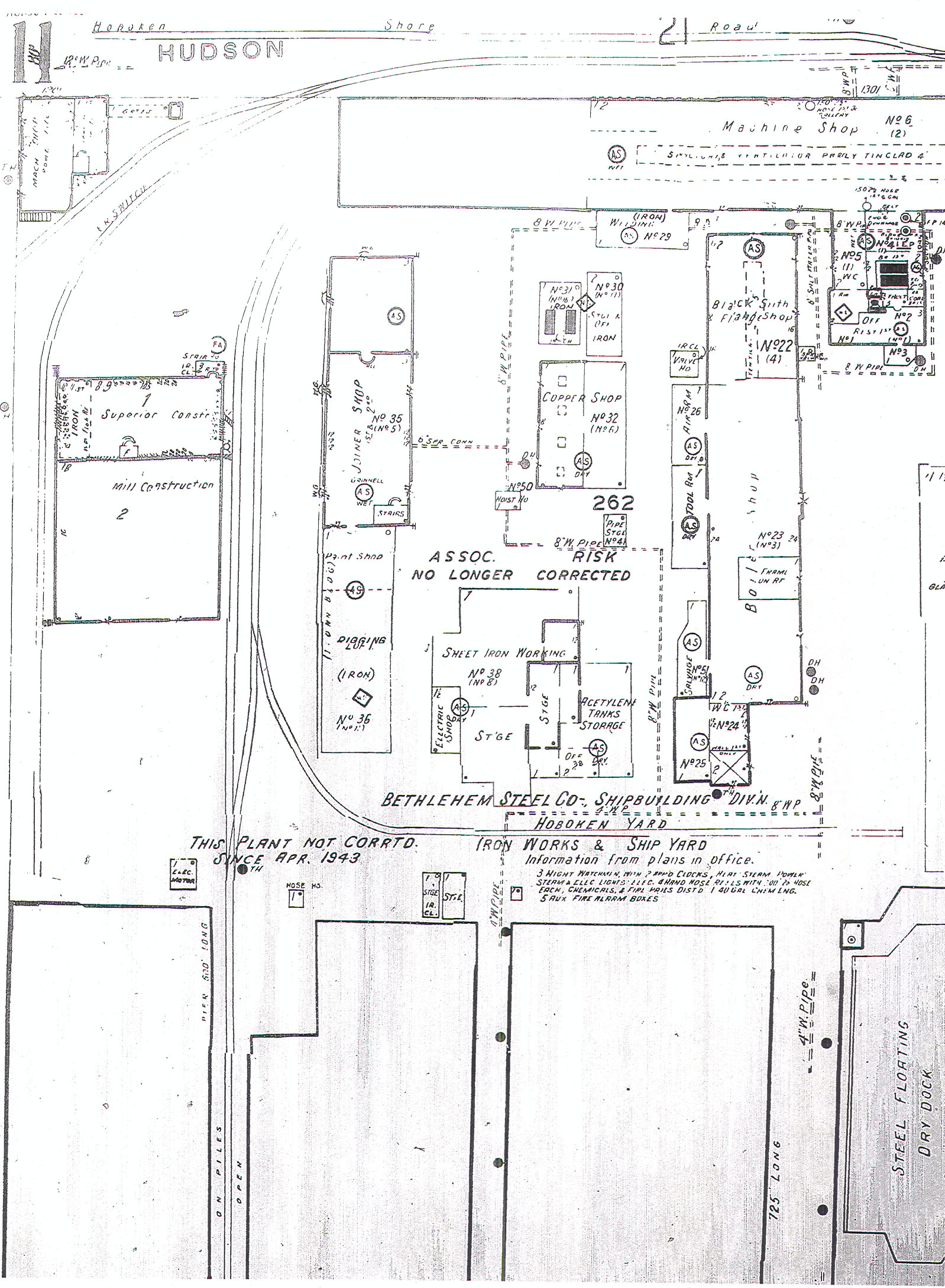

- Sanborn Maps

- Timeline-Freight Cars

- Train length and layout design

- Uncoupling methods

- Vertical curves

Layout Hints and Tips

Blocks

A "Block" is a group of cars that will be handled together from a location to the next place the cars are classified, interchanged, change trains or spotted at industry. The cars may be different final destinations. Blocks may be differentiated by :

- Final destination

- Interchange road

- Next switching location

- Car type

- Industry

- Direction

- Next train

Blocks are identified by a block name or code:

- Text name (Houston)

- Alphanumeric code (HOU1)

- Numeric code (135)

Blocks are used in classification yards to separate the cars. Each classification track may hold one or two blocks. Blocks are also used to assemble trains, a particular train sysmbol or schedule will carry only certain blocks. The blocking pattern is described in a "transportation plan" for the train. One special type of blocking, particularly used on locals, is station order blocking. The cars are blocked by the destination station and the train is assembled with the blocks in order from the front of the train to the rear of the train in the same order the train will arrive at the stations. So if a train originates at Anna and operates on the route Anna-Bess-Cloy-Dora-Eve-Fay, the train will be blocked:

Caboose-Fay-Eve-Dora-Cloy-Bess-Engines

It is also possible, that a train such as the one above may be blocked in the reverse manner as follows:

Caboose-Bess-Cloy-Dora-Eve-Fay-Engines

This will more likely be trains that run over several sub divsions where the blocks will be added and removed at crew change points by yard switchers.

Easyspline masonite roadbed

When I started in this hobby I used Woodland Scenics foam roadbed but after reading about Joe Fugate's Easyspline masonite roadbed I decided to try it out and WOW, what a difference.

I started by adding my risers made from 1 by 2.

I got the masonite splines from a local carpenter. They are made from 1/4 inch masonite and around 20 mm in height. Next time I will try to make these splines myself because I'm not 100% satisfied with the carpenter. I think it's importent to have the same size for all splines. In my case some are 20 mm, others are 22 and 21. That makes it hard to build a smooth roadbed.

I laminated 7 splines together to make the roadbed 42 mm wide (7 x 6). I used lots of spring clamps to hold them in place while the glue dried overnight.

Here are some closeup pictures of the finishing roadbed. Use a surform plan (I used one from Stanley) to take away the glue on the top and to make the roadbed smooth.

Next step is to glue the track directly to the roadbed with latex caulk. If you have gray ballast, use gray caulk.

Why do I like this method?

- I think this method is the best you can use for roadbed and I will never go back to any other method, never.

- It's easy to make curves and grades and it's VERY sturdy.

- You will not waste any material, one masonite board will go a long way.

- And you can use it for any scale, just laminate splines until you have the right size.

Try it out, I'm sure you will like it. Thanks to Joe Fugate for showing me this roadbed construction method.

(And thanks to Lee Nicholas for showing it to me -- Joef)

Timeline-Freight cars

1883 - Safety Appliance act passed.

1900 - Cars required to be equipped with

air brakes and knuckle couplers.

1911 - Safety Appliance Act amended to include ladders and grabirons.

1928 - Wood draft sills banned from interchange.

1933 - Type E or F couplers required on all new cars.

1933 - Rotary uncoupling levers required on new or rebuilt cars.

1934 -

AAR created from

ARA.

1937 - AB brakes required on all new cars.

1937 - Geared handbrakes are required on new or rebuilt cars.

1938 - Billboard cars banned.

1940 - Arch bar trucks banned in interchange service.

1945 - Wood running boards outlawed on new cars.

1948 - Plate B adopted, maximum height of 15 ft 1 in.

1954 - K brakes are banned in interchange service.

1957 - Trucks with cast journal boxes required (Andrews type trucks banned).

1958 - Cast iron wheels banned on new cars.

1959 - Allied Full Cushion trucks banned.

1963 - Plate C adopted, maximum height of 15 ft 6 in.

1966 - Roof running boards are banned.

1967 - High mounted brake wheels on new cars are banned.

1968 - ACI labels are installed.

1970 - Cast iron banned in interchange.

1970 - No underframes over 50 years old premitted.

1972 - ACI labels no longer required.

1972 - Roller bearings required on all 6 1/2 x 11 journals.

Train length and layout design

How you design your layout's passing sidings, yard tracks, and return loops can have a major impact on train length. In this tip we discuss briefly what the issues are.

You can have trains longer than passing sidings and yard tracks and can deal with them, although they will slow things down a lot. But a train longer than a reverse loop will not work -- the laws of physics says two objects cannot occupy the same space at the same time — so the front of your too-long-for-the-reverse-loop train will collide with the back of the train once it reaches the end of the loop!

With passing sidings, the key is opposing trains. As long as one of the two opposing trains will fit, the other train can be any length — you can get the trains past each other with a bit of advance planning. But if both trains are too long for the siding, you'll need to do a double-sawby maneuver. Such a maneuver is fun once in a while but it would get old if it was standard operating procedure. This means passing siding length has a major impact on train length if you want opposing traffic to flow smoothly.

With visible yards on the layout, a too-long train can always "double the yard", which means you split the train in two and it takes two yard tracks. This practice is not uncommon on the prototype so it could be an acceptable operating procedure as long as you are aware that it will slow down yard operation somewhat.

Finally, too-short staging tracks can be a problem, since it will make you "double the yard" in staging as well. Requiring trains to do this in a visible yard on the layout is one thing, but requiring this in staging is going to get old, so the recommendation is don't. Staging track length has a major influence on train length.

More information

Layout design analysis article on Joe Fugate's Siskiyou Line web site

Vertical Curves

The topic of vertical curves has been generating a lot of discussion lately, with a variety of standards being proposed -- both with and without experiential or computational justification. The purpose of this page is to list and discuss the various standards that various groups and individual modelers have established, along with the scale, gauge, and type of equipment used. Of particular interest will be designs that did not work for some reason. Please feel free to add your own experiences here, so long as there is enough data for it to be compared.